Water Cooled Kickless cables

FLPPL is proud of its advanced design in alternate polarity cables. Our high quality standards and simple, exclusive and efficient design have been proven for the past 3 decades.

Features

• End Connections are machined from solid electrolytic copper bar stock, which gives mechanical strength and high conductivity.

• Alternate positioning of copper conductors to maintain equal distribution of water flow throughout the cable.

• Unique end connection design with large un-obstructed water flow passage.

• Individual sockets for the ropes at the end connections. Each of the six ropes are first crimped and then soldered to their positions.

• Perfect separation of +ve and –ve by triangular perforated insulation tube makes desired space between the cable and the outer hose, which contribute to highest flexibility and uniform water-cooling of the conductor ropes.

• Each copper rope is made from 33 SWG hard-pitched electrolytic copper wires for greater flexibility and reduced wear points.

• The entire cable is arranged in such a way so that it attains the least possible inductive reactance and impedance.

• Single clamp on each side for easy movement.

• Long life, which is the true basis of evaluating any cable.

There options of hoses are available to meet your exact application

• Extra flexible for extreme bending operations

• Light duty

• Tough anti-abrasion cover

Standard Sizes available

• 300, 350, 375, 400 and 500 MCM

Standard Length

0.5 Mtrs Upto 4 Mtrs.

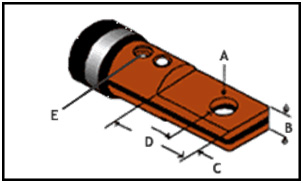

End Connections

• End connections can be made as per drawings provided by the client.

To order the type of end connection you need, you have to give us the dimensions of A, B, C, D and E (1/4" BSP or 1/4" NPT).

JUMPERS

• Water-cooled jumpers are manufactured using flexible copper ropes arranged in concentric layout to minimize “Skin Effect”.

• Full-length spring is placed through the entire length of the cable to ensure free flow water passage. Acute bending and kinking will not reduce water flow.

• The copper conductor assembly is crimped and then soldered.

• Strain relief flared copper tube at the end connection joint, which prevents annealing and solder wicking of copper conductors, which is often the cause of pre-mature failure.

End Connections

• Various types of end connections available – straight, pin, threaded and bend types available.